Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Polyamide 6 MXD6 GF50 PA6-MXD6

LONGZHENG

MXD6/PA6G50NC

PA6-MXD6 Polyamide 6 MXD6 GF50 showcases a range of superior mechanical properties, including high tensile strength, flexural strength, flexural modulus, and excellent impact resistance. These attributes make it an ideal choice for various industrial applications, particularly in environments that demand high strength, rigidity, and thermal stability.

LONGZHENG

MXD6/PA6G50NC

PA6-MXD6

PA6-MXD6 Polyamide 6 MXD6 GF50 is a high-performance reinforced polyamide 6 (PA6) material. Its unique mechanical properties and chemical stability make it an ideal choice for various application fields. This product demonstrates superior physical and mechanical performance through strict ISO standard testing.

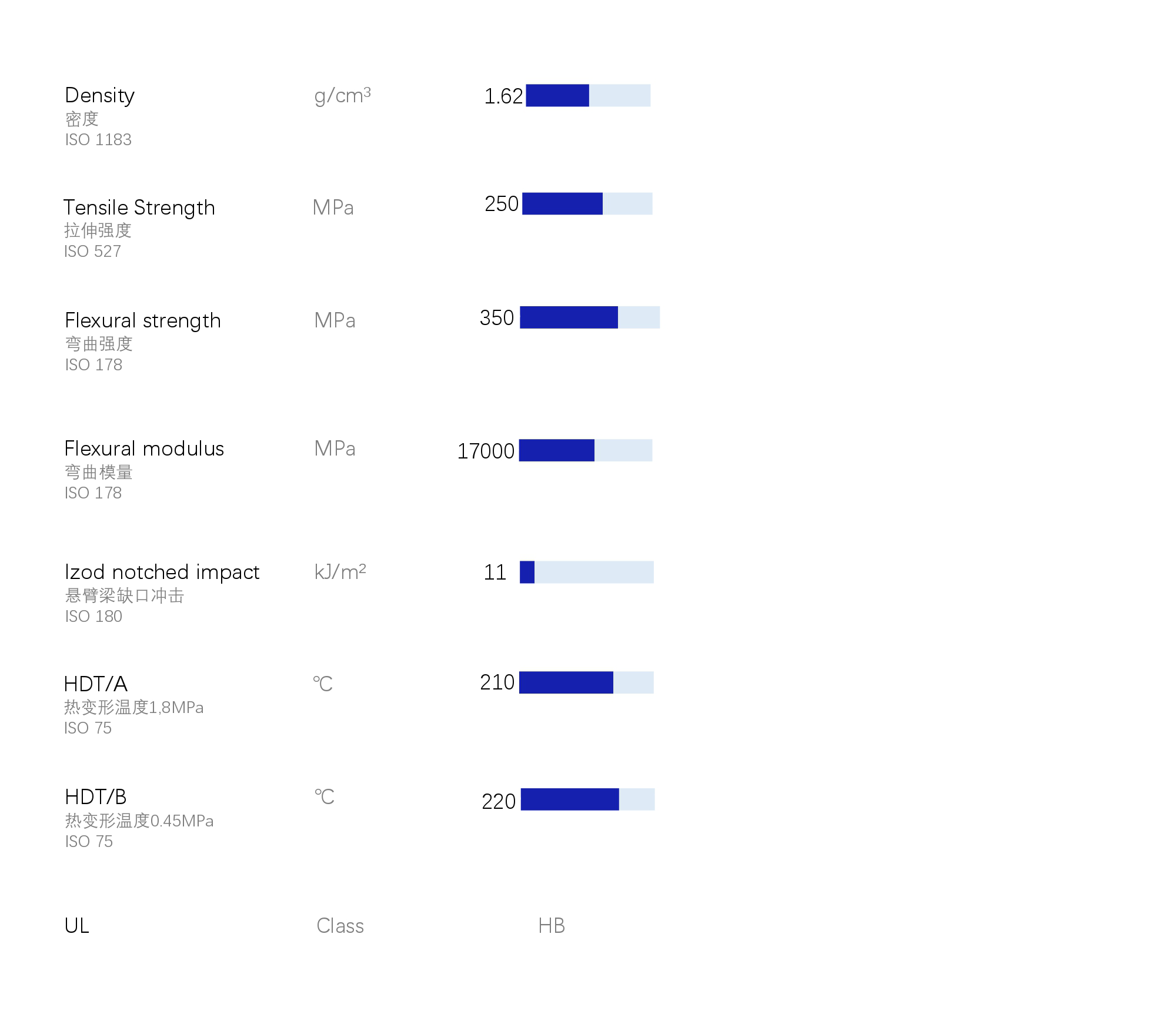

PA6-MXD6 Mechanical Properties:

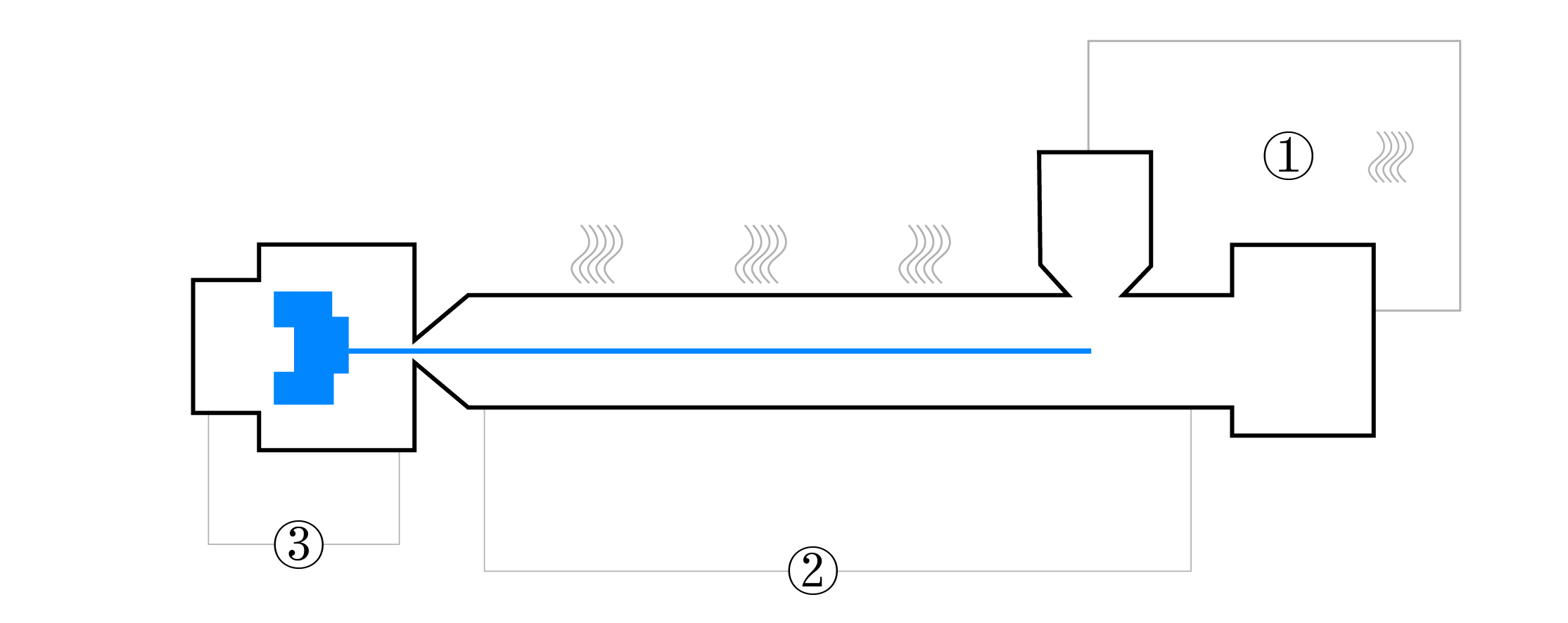

Processing Information:

To achieve the desired mechanical and thermal properties, it is crucial to follow a precise handling and molding process for LONGZHENG MXD6/PA6G50NC (PA6-MXD6 ).

Product Features and Advantages of the MXD6/PA6G50NC

1. The high density indicates that the material possesses a significant mass per volume, typically reflecting its dense molecular structure. Such density enhances the material's hardness and rigidity, making it suitable for applications that require withstanding high stress and pressure.

2. Tensile strength measures a material's resistance to tensile stress. A tensile strength of 250 MPa indicates the material's stability and strength when subjected to tension. This means the material is less prone to breakage or deformation under stretching or twisting applications.

3. The flexural modulus indicates the material's stiffness when bent or flexed. A flexural modulus of 350 MPa suggests that MXD6/PA6G50NC has high stiffness, making it highly beneficial for applications that require support or maintaining shape.

4. Flexural strength represents the maximum stress a material can withstand when bent. A flexural strength of 17000 MPa indicates the material's toughness and resistance to fracture when subjected to bending or torsion.

5. This value denotes the material's toughness when impacted. An Izod notched impact strength of 11 kJ/m2 indicates that MXD6/PA6G50NC exhibits considerable durability and toughness against impacts or compressions.

6. These temperatures indicate the points at which the material begins to soften or deform under different pressures. The HDT/A and HDT/B temperatures of 210 °C and 220 °C, respectively, show that MXD6/PA6G50NC possesses excellent stability and heat resistance in high-temperature environments.

7. A UL Class HB rating suggests that the material has a certain degree of flame retardancy. In specific industrial and application fields, flame retardancy is a critical safety requirement, especially in high-temperature or flammable environments.